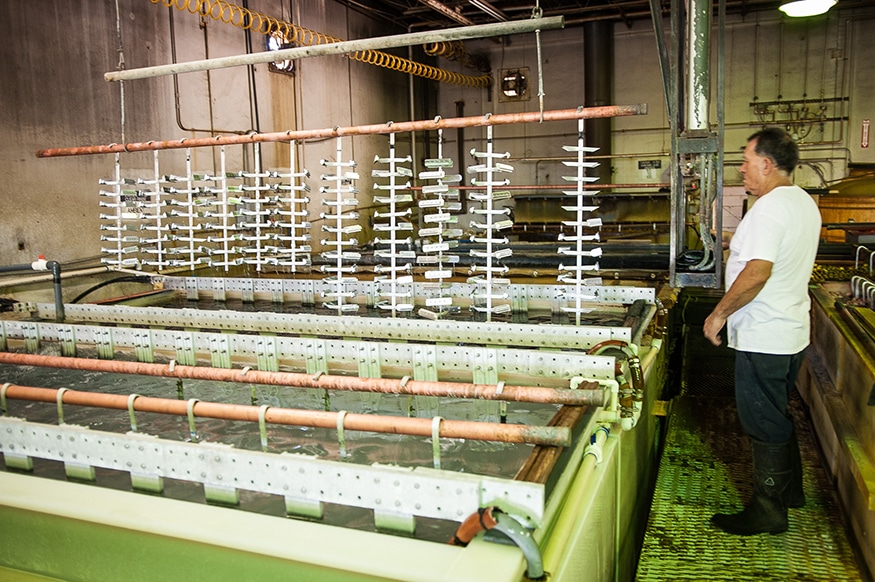

Anodizing Metal Coating Process

Anodizing is a process which helps to strengthen the overall body of a piece of metal. This metal coating process is used in many industries and is most commonly practiced in the designing of aircraft and vehicles. After the anodizing process has been completed, the finished product is a stronger and longer-lasting material designed for our customers’ specifications.

Mil-A-8625

- Type 1 – Class 1

- This anodizing process, often called the “Bengough-Stuart process,” is the most traditional method for anodizing metals. This process utilizes chromic acid to produce a durable film around the treated metal and can be used to create a clear or a colored finish. This finish protects against metal corrosion, paint adhesion, and offers additional resistance fatigue. This process is often used as a pre-painting treatment.

- Type 1B – Class 1

- This anodizing process is similar to Type 1 in that it used for the treatment of aluminum or aluminum alloys using chromic acid. Type 1B is differs from Type 1A because of its use of low voltage (20 volts). This process also usually involves higher temperatures and a higher concentration of chromic acid electrolytes.

- Type 2 – Class 1 & 2

- The coating process involves a bathing of sulfuric acid instead of the conventional chromic acid in order to provide a stronger seal and better corrosion resistance. Sulfuric Acid anodizing is generally preferred method of anodizing and is most commonly used for aircraft and military vehicles. Class 1 involves a colorless finish, while Class 2 involves the application of a finish color.

- Type 2B – Class 1

- The Type 2B – Class 1 anodizing process is similar to Type 2 in that it involves a bathing of sulfuric acid instead of the conventional chromic acid in order to provide a stronger seal and better corrosion resistance. Type 2B differs from Type 2 because it is for use as a non-chromate alternative for Type I and IB coatings and is a thin film sulfuric acid anodize.

Colors Available: Red, Black, Blue, Yellow, Clear, Purple, and Green

Anodics, Inc. is Nadcap™ Accredited for Aerospace Quality Systems and Chemical Processing.